Understanding your car tyre

01 Sep 2007|40,448 views

How a tyre is made

Tyre production is a complex technical process which requires stringent monitoring and quality control. This process consists of several manufacturing stages as stated below.

Tread Patterns and Characteristics

Markings on a tyre

On every tyre, you will be able to see some standard marking which describes the properties of the tyre. The markings include brand and model name of the tyre, tyre size, tyre aspect ratio, construction type, size of rim, loading rating and speed rating. A common string of numbers and letters can be seen on all tyres that look like this; 225/50 R 16 92V. A tread wear indicator is normally found on a tyre which indicate when you should change your tyre.

Brand and Model Name

This states the brand and model name for the specific tyre. The model name will differ with different tread patterns and functions.

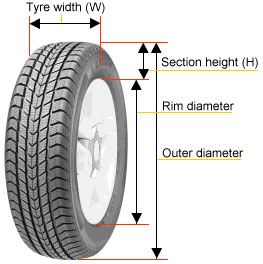

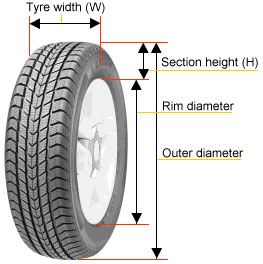

Tyre Size

The first set of digits in the string of numbers and letters represent the tyre size. As shown in the example above, the first 3 digits represent the width of the tyre in millimeters.

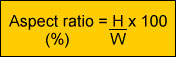

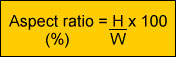

Aspect Ratio

The next pair of digits represents the sidewall aspect ratio. This is the ratio of the tyre's width to its height. 50 in this case mean that the tyre has a height that is equal to 50% of its width. Tyres with an aspect ratio of 50 and below are referred to as low profile tyres.

Construction Type

The letter that follows (normally an R) represents the construction type of the tyre. R represents radial construction which is the most common type seen for passenger cars nowadays.

Loading Rating

The loading rating, also known as the load-index figure, is imprinted on the sidewall of the tyre. It denotes the maximum load capacity of a tyre when driven at maximum speed. A list of load indices (Li) and maximum weights (kg) is give below:

Speed Rating

Tread Wear Indicator

The tread wear indicator can normally be found on the shoulder or upper sidewall part of the tyres. They are normally located in the grooves, evenly spaced out over the tyre. These markers on the tyre will indicate the age of the tyre.

As you use the tyre more often, the tread pattern will eventually become flush with the remainder of the tread. This is a sign to change your tyre. The lack of tread depth implies poor control of the vehicle and may cause an accident.

Related Articles

Tyre production is a complex technical process which requires stringent monitoring and quality control. This process consists of several manufacturing stages as stated below.

| • | Mixing |

| Based on the required performance parameters, a specific composition is created to produce the most suitable tyre. Various grades of natural and synthetic rubber are blended together and mixed with carbon black and other chemical products. | |

| • | Calendering |

| Textile fabric such as nylon, rayon and polyester are used for the casing and cap plies while steel cords are used for the belts. Both are coated with a film of rubber on both sides in the calendering process. | |

| • | Tread and Sidewall Extrusion |

| The mixture of rubber is fed into an extruder which will produce continuous lengths of tread rubber. The rubber will be cut to specific lengths. | |

| • | Bead Construction |

| For each particular tyre, steel wires are wounded on a bead former to become a bead core. The number of turns the steel wires are wounded will determine the diameter and strength for the tyre. | |

| • | Tyre Building |

| The inner liner, body plies and sidewalls are placed on a building drum. The ply edges are wrapped around the bead core; the sidewalls are then moved into position. The tyre is shaped by inflation with two belts afterwhich a cap ply and treads are added. | |

| • | Curing |

| The intermediate product is placed in a mould and cured in a curing press for a specific length of time, pressure and temperature. Once cured, the tyre is ejected from the mould. | |

| • | Trimming |

| Excess rubber is trimmed from the cured tyre mechanically. | |

| • | Inspection |

| Every tyre upon completion will be inspected visually and electronically to ensure uniformity and quality. Once checked, it will be sent for dispatch to be sold in the market. |

Tread Patterns and Characteristics

| Tread Pattern | Advantages | Disadvantages | Used for | ||||||||||||||

Rib shape: Patterns dominated by multiple circumferential grooves |

|

|

| ||||||||||||||

Lug shape: Patterns with the groove arrangement perpendicular to the circumference of the tyre |

|

|

| ||||||||||||||

Rib-Lug shape: Combination of Rib and Lug |

|

| |||||||||||||||

Block-shape: Patterns consisting of independent blocks divided by circumferential and lateral grooves. |

|

|

| ||||||||||||||

Asymmetric: Patterns differ on either side of the tyre. |

|

|

| ||||||||||||||

Directional pattern: Lateral grooves on both sides of the tyre which point in the same direction. |

|

|

|

Markings on a tyre

On every tyre, you will be able to see some standard marking which describes the properties of the tyre. The markings include brand and model name of the tyre, tyre size, tyre aspect ratio, construction type, size of rim, loading rating and speed rating. A common string of numbers and letters can be seen on all tyres that look like this; 225/50 R 16 92V. A tread wear indicator is normally found on a tyre which indicate when you should change your tyre.

Brand and Model Name

This states the brand and model name for the specific tyre. The model name will differ with different tread patterns and functions.

Tyre Size

The first set of digits in the string of numbers and letters represent the tyre size. As shown in the example above, the first 3 digits represent the width of the tyre in millimeters.

Aspect Ratio

The next pair of digits represents the sidewall aspect ratio. This is the ratio of the tyre's width to its height. 50 in this case mean that the tyre has a height that is equal to 50% of its width. Tyres with an aspect ratio of 50 and below are referred to as low profile tyres.

|  |

Construction Type

The letter that follows (normally an R) represents the construction type of the tyre. R represents radial construction which is the most common type seen for passenger cars nowadays.

Loading Rating

The loading rating, also known as the load-index figure, is imprinted on the sidewall of the tyre. It denotes the maximum load capacity of a tyre when driven at maximum speed. A list of load indices (Li) and maximum weights (kg) is give below:

Li | kg | Li | kg |

65 | 290 | 94 | 670 |

66 | 300 | 95 | 690 |

67 | 307 | 96 | 710 |

68 | 315 | 97 | 730 |

69 | 325 | 98 | 750 |

70 | 335 | 99 | 775 |

71 | 345 | 100 | 800 |

72 | 355 | 101 | 825 |

73 | 365 | 102 | 850 |

74 | 375 | 103 | 875 |

75 | 387 | 104 | 900 |

76 | 400 | 105 | 925 |

77 | 412 | 106 | 950 |

78 | 425 | 107 | 975 |

79 | 237 | 108 | 1000 |

80 | 450 | 109 | 1030 |

81 | 462 | 110 | 1060 |

82 | 475 | 111 | 1090 |

83 | 487 | 112 | 1120 |

84 | 500 | 113 | 1150 |

85 | 515 | 114 | 1180 |

86 | 530 | 115 | 1215 |

87 | 545 | 116 | 1250 |

88 | 560 | 117 | 1285 |

89 | 580 | 118 | 1320 |

90 | 600 | 119 | 1360 |

91 | 615 |

|

|

92 | 630 |

|

|

93 | 650 |

|

|

Speed Rating

Speed symbol | Maximum speed (km/h) | mph |

N | 140 | 87 |

P | 150 | 93 |

Q | 160 | 99 |

R | 170 | 106 |

S | 180 | 112 |

T | 190 | 118 |

H | 210 | 130 |

V | 240 | 149 |

W | 270 | 168 |

Y | 300 | 186 |

Speed category | Maximum speed km/h | mph |

ZR | >240 | >149 |

Tread Wear Indicator

The tread wear indicator can normally be found on the shoulder or upper sidewall part of the tyres. They are normally located in the grooves, evenly spaced out over the tyre. These markers on the tyre will indicate the age of the tyre.

As you use the tyre more often, the tread pattern will eventually become flush with the remainder of the tread. This is a sign to change your tyre. The lack of tread depth implies poor control of the vehicle and may cause an accident.

|  |

Related Articles

| • | Selecting the right tyre and wheel size |

| • | All about tyre balancing |

How a tyre is made

Tyre production is a complex technical process which requires stringent monitoring and quality control. This process consists of several manufacturing stages as stated below.

Tread Patterns and Characteristics

Markings on a tyre

On every tyre, you will be able to see some standard marking which describes the properties of the tyre. The markings include brand and model name of the tyre, tyre size, tyre aspect ratio, construction type, size of rim, loading rating and speed rating. A common string of numbers and letters can be seen on all tyres that look like this; 225/50 R 16 92V. A tread wear indicator is normally found on a tyre which indicate when you should change your tyre.

Brand and Model Name

This states the brand and model name for the specific tyre. The model name will differ with different tread patterns and functions.

Tyre Size

The first set of digits in the string of numbers and letters represent the tyre size. As shown in the example above, the first 3 digits represent the width of the tyre in millimeters.

Aspect Ratio

The next pair of digits represents the sidewall aspect ratio. This is the ratio of the tyre's width to its height. 50 in this case mean that the tyre has a height that is equal to 50% of its width. Tyres with an aspect ratio of 50 and below are referred to as low profile tyres.

Construction Type

The letter that follows (normally an R) represents the construction type of the tyre. R represents radial construction which is the most common type seen for passenger cars nowadays.

Loading Rating

The loading rating, also known as the load-index figure, is imprinted on the sidewall of the tyre. It denotes the maximum load capacity of a tyre when driven at maximum speed. A list of load indices (Li) and maximum weights (kg) is give below:

Speed Rating

Tread Wear Indicator

The tread wear indicator can normally be found on the shoulder or upper sidewall part of the tyres. They are normally located in the grooves, evenly spaced out over the tyre. These markers on the tyre will indicate the age of the tyre.

As you use the tyre more often, the tread pattern will eventually become flush with the remainder of the tread. This is a sign to change your tyre. The lack of tread depth implies poor control of the vehicle and may cause an accident.

Related Articles

Tyre production is a complex technical process which requires stringent monitoring and quality control. This process consists of several manufacturing stages as stated below.

| • | Mixing |

| Based on the required performance parameters, a specific composition is created to produce the most suitable tyre. Various grades of natural and synthetic rubber are blended together and mixed with carbon black and other chemical products. | |

| • | Calendering |

| Textile fabric such as nylon, rayon and polyester are used for the casing and cap plies while steel cords are used for the belts. Both are coated with a film of rubber on both sides in the calendering process. | |

| • | Tread and Sidewall Extrusion |

| The mixture of rubber is fed into an extruder which will produce continuous lengths of tread rubber. The rubber will be cut to specific lengths. | |

| • | Bead Construction |

| For each particular tyre, steel wires are wounded on a bead former to become a bead core. The number of turns the steel wires are wounded will determine the diameter and strength for the tyre. | |

| • | Tyre Building |

| The inner liner, body plies and sidewalls are placed on a building drum. The ply edges are wrapped around the bead core; the sidewalls are then moved into position. The tyre is shaped by inflation with two belts afterwhich a cap ply and treads are added. | |

| • | Curing |

| The intermediate product is placed in a mould and cured in a curing press for a specific length of time, pressure and temperature. Once cured, the tyre is ejected from the mould. | |

| • | Trimming |

| Excess rubber is trimmed from the cured tyre mechanically. | |

| • | Inspection |

| Every tyre upon completion will be inspected visually and electronically to ensure uniformity and quality. Once checked, it will be sent for dispatch to be sold in the market. |

Tread Patterns and Characteristics

| Tread Pattern | Advantages | Disadvantages | Used for | ||||||||||||||

Rib shape: Patterns dominated by multiple circumferential grooves |

|

|

| ||||||||||||||

Lug shape: Patterns with the groove arrangement perpendicular to the circumference of the tyre |

|

|

| ||||||||||||||

Rib-Lug shape: Combination of Rib and Lug |

|

| |||||||||||||||

Block-shape: Patterns consisting of independent blocks divided by circumferential and lateral grooves. |

|

|

| ||||||||||||||

Asymmetric: Patterns differ on either side of the tyre. |

|

|

| ||||||||||||||

Directional pattern: Lateral grooves on both sides of the tyre which point in the same direction. |

|

|

|

Markings on a tyre

On every tyre, you will be able to see some standard marking which describes the properties of the tyre. The markings include brand and model name of the tyre, tyre size, tyre aspect ratio, construction type, size of rim, loading rating and speed rating. A common string of numbers and letters can be seen on all tyres that look like this; 225/50 R 16 92V. A tread wear indicator is normally found on a tyre which indicate when you should change your tyre.

Brand and Model Name

This states the brand and model name for the specific tyre. The model name will differ with different tread patterns and functions.

Tyre Size

The first set of digits in the string of numbers and letters represent the tyre size. As shown in the example above, the first 3 digits represent the width of the tyre in millimeters.

Aspect Ratio

The next pair of digits represents the sidewall aspect ratio. This is the ratio of the tyre's width to its height. 50 in this case mean that the tyre has a height that is equal to 50% of its width. Tyres with an aspect ratio of 50 and below are referred to as low profile tyres.

|  |

Construction Type

The letter that follows (normally an R) represents the construction type of the tyre. R represents radial construction which is the most common type seen for passenger cars nowadays.

Loading Rating

The loading rating, also known as the load-index figure, is imprinted on the sidewall of the tyre. It denotes the maximum load capacity of a tyre when driven at maximum speed. A list of load indices (Li) and maximum weights (kg) is give below:

Li | kg | Li | kg |

65 | 290 | 94 | 670 |

66 | 300 | 95 | 690 |

67 | 307 | 96 | 710 |

68 | 315 | 97 | 730 |

69 | 325 | 98 | 750 |

70 | 335 | 99 | 775 |

71 | 345 | 100 | 800 |

72 | 355 | 101 | 825 |

73 | 365 | 102 | 850 |

74 | 375 | 103 | 875 |

75 | 387 | 104 | 900 |

76 | 400 | 105 | 925 |

77 | 412 | 106 | 950 |

78 | 425 | 107 | 975 |

79 | 237 | 108 | 1000 |

80 | 450 | 109 | 1030 |

81 | 462 | 110 | 1060 |

82 | 475 | 111 | 1090 |

83 | 487 | 112 | 1120 |

84 | 500 | 113 | 1150 |

85 | 515 | 114 | 1180 |

86 | 530 | 115 | 1215 |

87 | 545 | 116 | 1250 |

88 | 560 | 117 | 1285 |

89 | 580 | 118 | 1320 |

90 | 600 | 119 | 1360 |

91 | 615 |

|

|

92 | 630 |

|

|

93 | 650 |

|

|

Speed Rating

Speed symbol | Maximum speed (km/h) | mph |

N | 140 | 87 |

P | 150 | 93 |

Q | 160 | 99 |

R | 170 | 106 |

S | 180 | 112 |

T | 190 | 118 |

H | 210 | 130 |

V | 240 | 149 |

W | 270 | 168 |

Y | 300 | 186 |

Speed category | Maximum speed km/h | mph |

ZR | >240 | >149 |

Tread Wear Indicator

The tread wear indicator can normally be found on the shoulder or upper sidewall part of the tyres. They are normally located in the grooves, evenly spaced out over the tyre. These markers on the tyre will indicate the age of the tyre.

As you use the tyre more often, the tread pattern will eventually become flush with the remainder of the tread. This is a sign to change your tyre. The lack of tread depth implies poor control of the vehicle and may cause an accident.

|  |

Related Articles

| • | Selecting the right tyre and wheel size |

| • | All about tyre balancing |