BMW Plant Dingolfing gets new electric furnace

17 May 2023|1,185 views

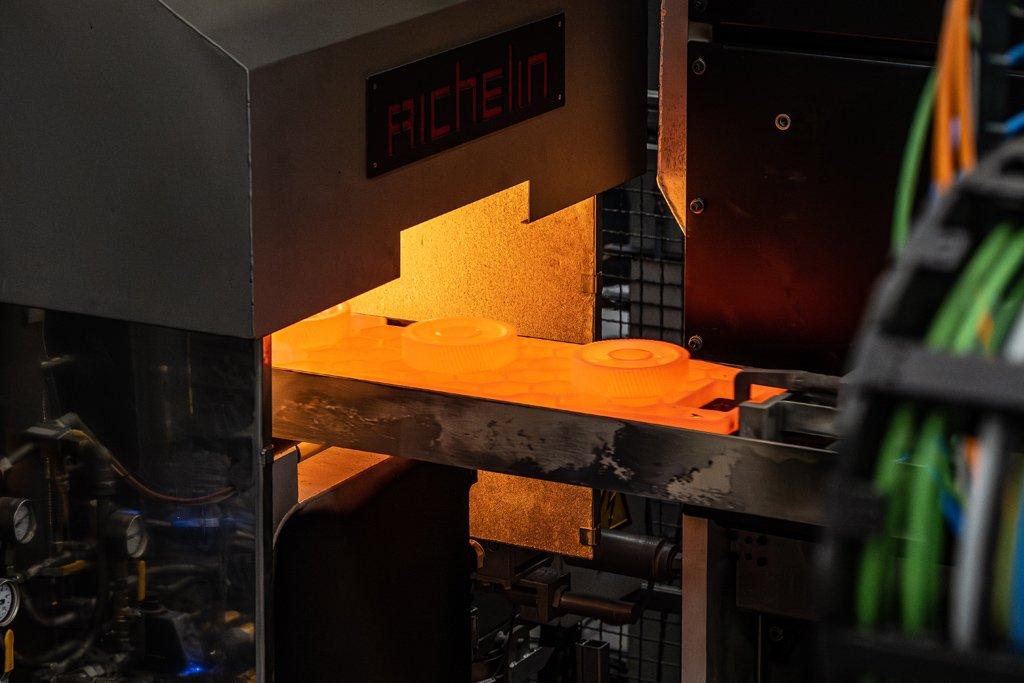

BMW has announced that Plant Dingolfing - where models including the 4 Series, iX, and 7 Series, amongst others are made - is now operating a new electrically heated ring hearth furnace.

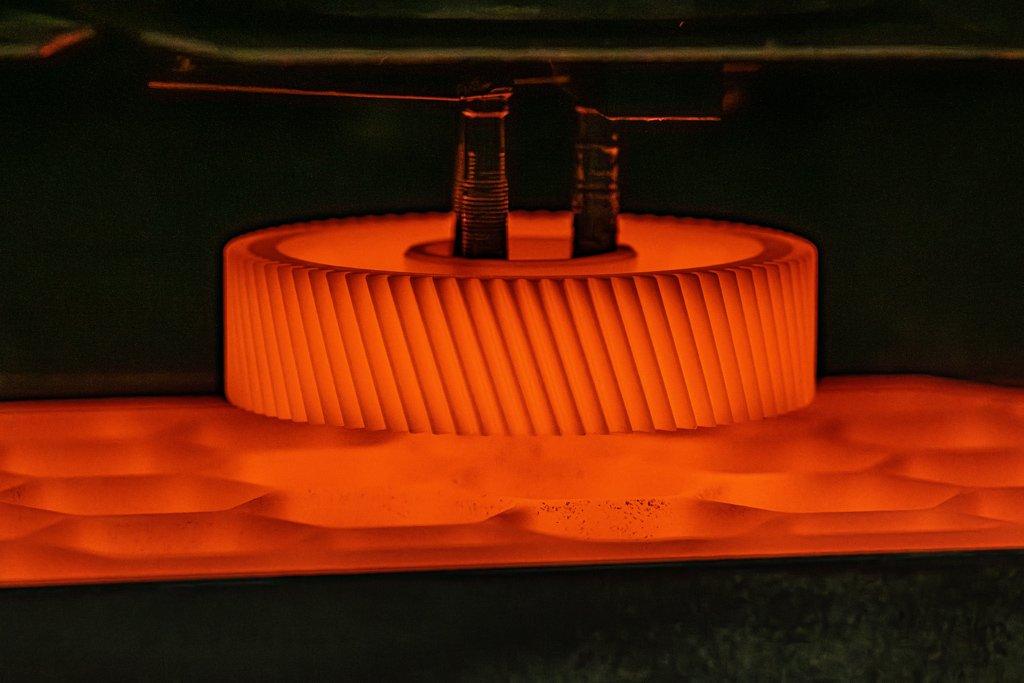

The furnace is used to harden component parts, which BMW states has seen increased demand as electric mobility ramps up, driving up the need for electric drives, and necessitating the installment of a new furnace with a fixture hardening press.

With a production capacity of approximately 960,000 spur gears a year, this new electric furnace makes use of power-to-heat technology, allowing it to heat up to 900 degrees Celsius and replace the use of 33 gas flames in ceramic-jacketed pipes, which will save the site some 300 tonnes of CO2 a year compared to a gas-powered equivalent.

BMW's Dingolfing already makes use of regional green hydroelectricity to manufacture the iX.

The furnace is used to harden component parts, which BMW states has seen increased demand as electric mobility ramps up, driving up the need for electric drives, and necessitating the installment of a new furnace with a fixture hardening press.

With a production capacity of approximately 960,000 spur gears a year, this new electric furnace makes use of power-to-heat technology, allowing it to heat up to 900 degrees Celsius and replace the use of 33 gas flames in ceramic-jacketed pipes, which will save the site some 300 tonnes of CO2 a year compared to a gas-powered equivalent.

BMW's Dingolfing already makes use of regional green hydroelectricity to manufacture the iX.

BMW has announced that Plant Dingolfing - where models including the 4 Series, iX, and 7 Series, amongst others are made - is now operating a new electrically heated ring hearth furnace.

The furnace is used to harden component parts, which BMW states has seen increased demand as electric mobility ramps up, driving up the need for electric drives, and necessitating the installment of a new furnace with a fixture hardening press.

With a production capacity of approximately 960,000 spur gears a year, this new electric furnace makes use of power-to-heat technology, allowing it to heat up to 900 degrees Celsius and replace the use of 33 gas flames in ceramic-jacketed pipes, which will save the site some 300 tonnes of CO2 a year compared to a gas-powered equivalent.

BMW's Dingolfing already makes use of regional green hydroelectricity to manufacture the iX.

The furnace is used to harden component parts, which BMW states has seen increased demand as electric mobility ramps up, driving up the need for electric drives, and necessitating the installment of a new furnace with a fixture hardening press.

With a production capacity of approximately 960,000 spur gears a year, this new electric furnace makes use of power-to-heat technology, allowing it to heat up to 900 degrees Celsius and replace the use of 33 gas flames in ceramic-jacketed pipes, which will save the site some 300 tonnes of CO2 a year compared to a gas-powered equivalent.

BMW's Dingolfing already makes use of regional green hydroelectricity to manufacture the iX.

Latest COE Prices

June 2025 | 1st BIDDING

NEXT TENDER: 18 Jun 2025

CAT A$96,999

CAT B$113,000

CAT C$62,000

CAT E$113,900

View Full Results Thank You For Your Subscription.