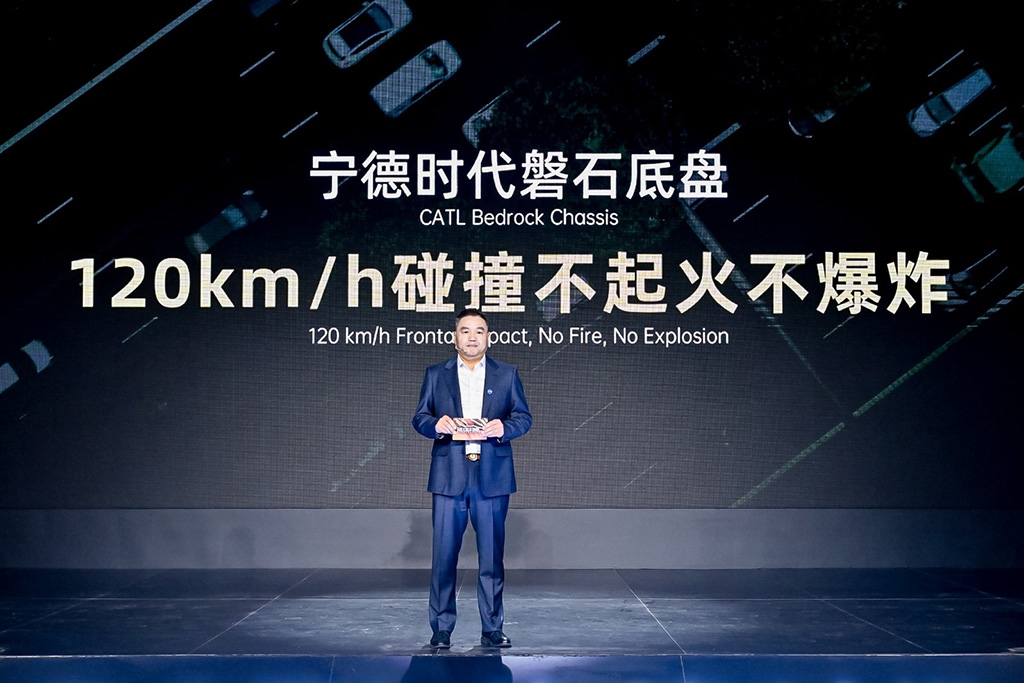

CATL launches the Bedrock Chassis

27 Dec 2024|95 views

CATL has announced that it has officially launched the Bedrock Chassis, the world's first ultra-safe skateboard chassis, able to withstand a frontal impact of 120km/h without catching fire or exploding.

Setting a new standard for intelligent chassis safety and with its battery-centered design, the chassis uses Cell-to-Chassis integration technology - directly integrating the battery cells into the chassis - to allow for a shared structural design. Based on the decoupling of the chassis from the upper body, it is capable of absorbing 85% of the vehicle's collision energy as compared to around 60% in traditional chassis.

The Bedrock Chassis features a three-dimensional biomimetic tortoise shell structure where the body and energy unit framework are integrated. In addition, its aircraft carrier-grade arresting structure disperses impact forces across multiple pathways during a crash, gradually decelerating the vehicle and significantly reducing the depth and speed at which obstacles intrude the cabin.

Its rigidity is further enhanced by its submarine-grade hot-formed steel with a strength of 2,000MPa and aerospace-grade aluminium alloy with a strength of 600MPa.

With a rich array of toolkits and solution packages, the chassis offers a scalable software and hardware architecture and standardised interfaces, enabling flexible configurations and allowing for a "one chassis architecture, multiple vehicle models" concept that improves development efficiency, reducing the time for mass production of a vehicle from the usual 36 months or longer to 12-18 months.

CATL has announced that it has officially launched the Bedrock Chassis, the world's first ultra-safe skateboard chassis, able to withstand a frontal impact of 120km/h without catching fire or exploding.

Setting a new standard for intelligent chassis safety and with its battery-centered design, the chassis uses Cell-to-Chassis integration technology - directly integrating the battery cells into the chassis - to allow for a shared structural design. Based on the decoupling of the chassis from the upper body, it is capable of absorbing 85% of the vehicle's collision energy as compared to around 60% in traditional chassis.

The Bedrock Chassis features a three-dimensional biomimetic tortoise shell structure where the body and energy unit framework are integrated. In addition, its aircraft carrier-grade arresting structure disperses impact forces across multiple pathways during a crash, gradually decelerating the vehicle and significantly reducing the depth and speed at which obstacles intrude the cabin.

Its rigidity is further enhanced by its submarine-grade hot-formed steel with a strength of 2,000MPa and aerospace-grade aluminium alloy with a strength of 600MPa.

With a rich array of toolkits and solution packages, the chassis offers a scalable software and hardware architecture and standardised interfaces, enabling flexible configurations and allowing for a "one chassis architecture, multiple vehicle models" concept that improves development efficiency, reducing the time for mass production of a vehicle from the usual 36 months or longer to 12-18 months.

Latest COE Prices

January 2026 | 2nd BIDDING

NEXT TENDER: 04 Feb 2026

CAT A$109,501

CAT B$121,634

CAT C$75,202

CAT E$120,891

View Full Results Thank You For Your Subscription.