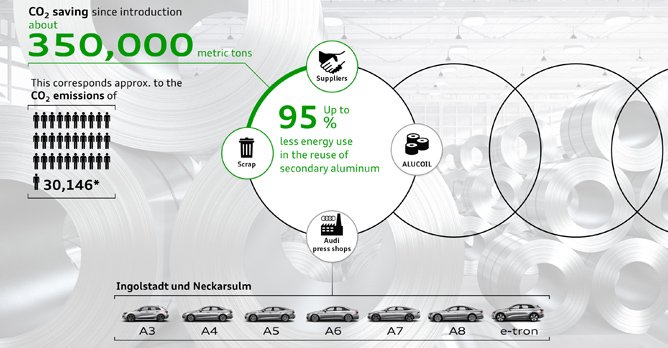

Audi saved over 350,000 tons of emissions with Aluminium Closed Loop

13 Jun 2020|424 views

Audi has a long tradition of using aluminum. The first Audi A8 with the Audi Space Frame, a pioneering achievement in lightweight construction, debuted in 1994.

Audi continues to use the lightweight metal in various components of what is now the fourth generation of the luxury sedan as part of an innovative multi-material mix.

Audi introduced the 'Aluminium Closed Loop' at the Neckarsulm site back in 2017. The aluminum sheet offcuts that are produced in the press shop are sent straight back to the supplier and recycled into aluminum sheets of equal quality, which Audi then uses in production.

At Neckarsulm, Audi now employs this Aluminum Closed Loop with two suppliers, thus increasing the amount of aluminum managed in the closed loop. This achieved a savings of roughly 150,000 metric tons of CO2 in 2019, two-thirds more than the year before.

Marco Philippi, Head of Procurement Strategy, commented, "The efficient and frugal use of resources is just as important to us as the reduction of our CO2 emissions. The energy input for the reuse of secondary aluminum is up to 95% lower than for the production of primary aluminum."

The Ingolstadt plant also recently introduced the Aluminum Closed Loop. The plant in Gyor plans to introduce it next year, with additional plants and model lines to follow in due course. Secondary aluminum is currently used in various body parts of the Audi A3, A4, A5, A6, A7 and A8, and also in parts of the Audi e-tron and e-tron Sportback.

Audi has a long tradition of using aluminum. The first Audi A8 with the Audi Space Frame, a pioneering achievement in lightweight construction, debuted in 1994.

Audi continues to use the lightweight metal in various components of what is now the fourth generation of the luxury sedan as part of an innovative multi-material mix.

Audi introduced the 'Aluminium Closed Loop' at the Neckarsulm site back in 2017. The aluminum sheet offcuts that are produced in the press shop are sent straight back to the supplier and recycled into aluminum sheets of equal quality, which Audi then uses in production.

At Neckarsulm, Audi now employs this Aluminum Closed Loop with two suppliers, thus increasing the amount of aluminum managed in the closed loop. This achieved a savings of roughly 150,000 metric tons of CO2 in 2019, two-thirds more than the year before.

Marco Philippi, Head of Procurement Strategy, commented, "The efficient and frugal use of resources is just as important to us as the reduction of our CO2 emissions. The energy input for the reuse of secondary aluminum is up to 95% lower than for the production of primary aluminum."

The Ingolstadt plant also recently introduced the Aluminum Closed Loop. The plant in Gyor plans to introduce it next year, with additional plants and model lines to follow in due course. Secondary aluminum is currently used in various body parts of the Audi A3, A4, A5, A6, A7 and A8, and also in parts of the Audi e-tron and e-tron Sportback.

Latest COE Prices

July 2025 | 1st BIDDING

NEXT TENDER: 23 Jul 2025

CAT A$101,102

CAT B$119,600

CAT C$66,689

CAT E$118,500

View Full Results Thank You For Your Subscription.