The first new Bentley Blower in 90 years

10 Dec 2020|1,108 views

After 40,000 hours of work, Bentley Mulliner has today completed the first new Bentley Blower in 90 years, with the delivery of Car Zero - the prototype car for the Blower Continuation Series.

This highly exclusive run of 12 customer cars - all pre-sold - will be crafted from the design drawings and tooling jigs used for the original four Blowers built and raced by Sir Henry 'Tim' Birkin in the late 1920s. Specifically, Bentley's own Team Car has provided the master model for the Continuation Series, with every single component laser-scanned as part of a wheels-up, sympathetic restoration.

Each of these parts and assemblies have been created by a project team of Bentley Mulliner engineers, craftspeople and technicians working together with a number of British specialists and suppliers.

Blower Car Zero is a dedicated test and development prototype, built in advance of the 12 customer cars, and will be subjected to months of durability and performance testing. Finished in gloss black, with an interior in Oxblood red leather from Bridge of Weir.

The first step in creating Car Zero was an extensive analysis of the original design drawings and drafts that were referenced in the creation of the original Blower Team Cars, together with archived period photographs of the cars.

Following a piece-by-piece disassembly of the #2 Team Car owned by Bentley and an exceptionally precise laser scanning of the frame and its components, a complete digital CAD model of the Blower was created. From there, a team of artisan specialists were recruited to start manufacturing the components that Bentley Mulliner would bring together to form the first Blower.

From the outset, Bentley Mulliner sought to engage the very best specialists across the country to create componentry for the Blower Continuation Series in a manner befitting such a project - using traditional techniques passed down through generations.

The chassis has been created in heavy-gauge steel, hand-formed and hot riveted by the specialists at Israel Newton & Sons Ltd. This 200-year old company, based near Derby, traditionally makes boilers for steam locomotives and traction engines, and as such has the skills to forge and shape metal in a traditional way.

The Vintage Car Radiator Company, based at Bicester Heritage, has crafted exact recreations of the some of the Blower's key components - including the mirror-polished, solid nickel silver radiator shell and the hand-beaten fuel tank formed in steel and copper.

The Blower's iconic headlamps have been reborn by Vintage Headlamp Restoration International Ltd in Sheffield. This father and son team is world-renowned for their silversmithing and ability to create vintage-design headlamps from original specifications.

Meanwhile, in the bespoke Mulliner Trim Shop in Crewe, a new ash frame created by Lomax Coachbuilders underwent final stages of carpentry with Mulliner's team of experts, including the application of 25m of highly specialised Rexine material used to wrap the body.

Hand-trimming of the body was then completed by Mulliner's master craftsmen. For Car Zero, the gloss black bodywork is paired with Oxblood red Bridge of Weir leather and matching trim. As per the originals, the seats are stuffed with a total of 10kg of natural horsehair.

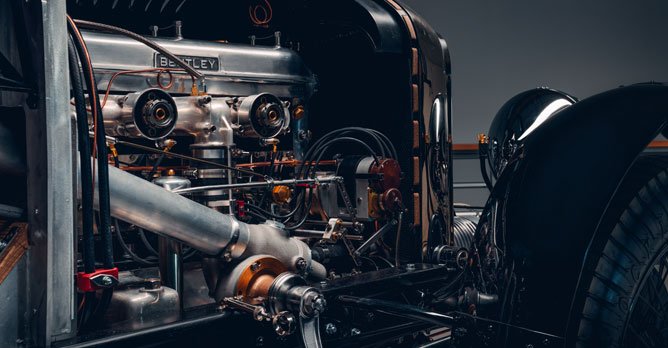

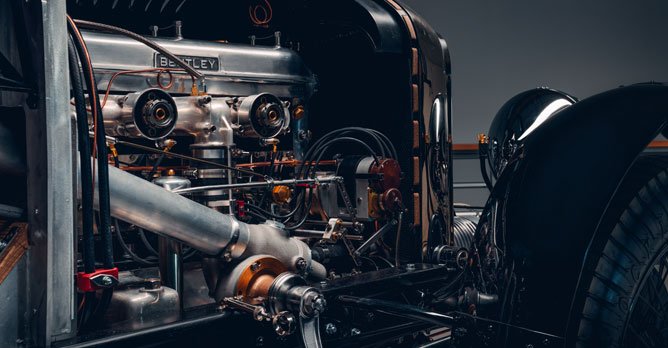

The renowned 4.5-litre engine has been paired with a newly machined Amherst Villiers roots-type supercharger. The newly created Blower engine is an exact recreation of the engines that powered Tim Birkin's four Team Blowers that raced in the late 1920s - including the use of magnesium for the crankcase.

While the first engine was being assembled, work was also underway to convert an engine testbed at Bentley's Crewe headquarters to accept the nearly 100-year old engine design. The engine test facility has been at Bentley since the factory was built in 1938, and the cells were originally used to run-in and power-test Merlin V12 aero engines produced by the factory for the Spitfire and Hurricane fighters of the Second World War.

Preparing the test bed involved making a replica Blower front chassis to hold the engine, which could then be mounted to the computer-controlled engine dynamometer. A new software version to measure and control the engine was written and tested, allowing Bentley's engineers to monitor and run the engine to precise parameters.

With the engine fully installed, the engine was put through a defined schedule of run-in ahead of fitment to the car. With the build of Car Zero now complete, a programme of real-world durability testing will begin. Sessions of gradually increasing duration and speed will check functionality and robustness under ever harder conditions.

The test programme is designed to achieve the equivalent of 35,000km of real-world driving across 8,000km of track driving, and simulates the undertaking of famous rallies such as Peking to Paris and Mille Miglia. The testing will also a particularly brave driver taking the car to its top speed - with Adrian Hallmark first in the queue.

After 40,000 hours of work, Bentley Mulliner has today completed the first new Bentley Blower in 90 years, with the delivery of Car Zero - the prototype car for the Blower Continuation Series.

This highly exclusive run of 12 customer cars - all pre-sold - will be crafted from the design drawings and tooling jigs used for the original four Blowers built and raced by Sir Henry 'Tim' Birkin in the late 1920s. Specifically, Bentley's own Team Car has provided the master model for the Continuation Series, with every single component laser-scanned as part of a wheels-up, sympathetic restoration.

Each of these parts and assemblies have been created by a project team of Bentley Mulliner engineers, craftspeople and technicians working together with a number of British specialists and suppliers.

Blower Car Zero is a dedicated test and development prototype, built in advance of the 12 customer cars, and will be subjected to months of durability and performance testing. Finished in gloss black, with an interior in Oxblood red leather from Bridge of Weir.

The first step in creating Car Zero was an extensive analysis of the original design drawings and drafts that were referenced in the creation of the original Blower Team Cars, together with archived period photographs of the cars.

Following a piece-by-piece disassembly of the #2 Team Car owned by Bentley and an exceptionally precise laser scanning of the frame and its components, a complete digital CAD model of the Blower was created. From there, a team of artisan specialists were recruited to start manufacturing the components that Bentley Mulliner would bring together to form the first Blower.

From the outset, Bentley Mulliner sought to engage the very best specialists across the country to create componentry for the Blower Continuation Series in a manner befitting such a project - using traditional techniques passed down through generations.

The chassis has been created in heavy-gauge steel, hand-formed and hot riveted by the specialists at Israel Newton & Sons Ltd. This 200-year old company, based near Derby, traditionally makes boilers for steam locomotives and traction engines, and as such has the skills to forge and shape metal in a traditional way.

The Vintage Car Radiator Company, based at Bicester Heritage, has crafted exact recreations of the some of the Blower's key components - including the mirror-polished, solid nickel silver radiator shell and the hand-beaten fuel tank formed in steel and copper.

The Blower's iconic headlamps have been reborn by Vintage Headlamp Restoration International Ltd in Sheffield. This father and son team is world-renowned for their silversmithing and ability to create vintage-design headlamps from original specifications.

Meanwhile, in the bespoke Mulliner Trim Shop in Crewe, a new ash frame created by Lomax Coachbuilders underwent final stages of carpentry with Mulliner's team of experts, including the application of 25m of highly specialised Rexine material used to wrap the body.

Hand-trimming of the body was then completed by Mulliner's master craftsmen. For Car Zero, the gloss black bodywork is paired with Oxblood red Bridge of Weir leather and matching trim. As per the originals, the seats are stuffed with a total of 10kg of natural horsehair.

The renowned 4.5-litre engine has been paired with a newly machined Amherst Villiers roots-type supercharger. The newly created Blower engine is an exact recreation of the engines that powered Tim Birkin's four Team Blowers that raced in the late 1920s - including the use of magnesium for the crankcase.

While the first engine was being assembled, work was also underway to convert an engine testbed at Bentley's Crewe headquarters to accept the nearly 100-year old engine design. The engine test facility has been at Bentley since the factory was built in 1938, and the cells were originally used to run-in and power-test Merlin V12 aero engines produced by the factory for the Spitfire and Hurricane fighters of the Second World War.

Preparing the test bed involved making a replica Blower front chassis to hold the engine, which could then be mounted to the computer-controlled engine dynamometer. A new software version to measure and control the engine was written and tested, allowing Bentley's engineers to monitor and run the engine to precise parameters.

The new Blower engine is an exact recreation of the engines used by the original Bentley Blower for racing during the 1920s

With the engine fully installed, the engine was put through a defined schedule of run-in ahead of fitment to the car. With the build of Car Zero now complete, a programme of real-world durability testing will begin. Sessions of gradually increasing duration and speed will check functionality and robustness under ever harder conditions.

The test programme is designed to achieve the equivalent of 35,000km of real-world driving across 8,000km of track driving, and simulates the undertaking of famous rallies such as Peking to Paris and Mille Miglia. The testing will also a particularly brave driver taking the car to its top speed - with Adrian Hallmark first in the queue.

Latest COE Prices

June 2025 | 2nd BIDDING

NEXT TENDER: 09 Jul 2025

CAT A$98,124

CAT B$116,670

CAT C$65,000

CAT E$116,889

View Full Results Thank You For Your Subscription.