Ever wondered how tyres are tested? Continental shows us

25 Jun 2025|686 views

We were invited to Hannover to experience Continental Tires' latest SUV-specific UltraContact UX7 tyres. As part of the programme, the brand curated a two-day itinerary for us to visit its research and development facility and its Contidrom test facility to learn more about how tyres are engineered and tested.

Tyres might seem much simpler than other components of a car, such as the engine or electrical components, but the development and testing process sure isn't simple.

A visit to the home of Continental's designers and engineers

While I've visited the Contidrom facility just last year, this was the first time that I've been invited to visit Continental's R&D Centre. The R&D Centre is home to a team of thousands of researchers, designers and engineers from all over the world, who develop and test the brand's products.

At Continental's R&D Centre, we got to visit several workshops and labs - sadly, photos and videos aren't allowed within most of these facilities.

An interesting one was the Non-Destructive Testing Tire Analysis lab. Over here, X-Ray Computer Tomography (CT Scans) are used to analyse tyres during the development process. This method allows the engineers to get a better understanding of what's happening to the construction of the tyre in various situations (i.e. compressing the tyre against a sharp edge and scanning it), and it can also be used to evaluate manufacturing processes of tyres.

Continental also has an Indoor Testing lab where tyre characteristics such as rolling resistance, static footprint, and static stiffness of the tyre are evaluated. There is also have a costly Flat Trac machine, which allows dynamic testing of tyres - the machine emulates actual driving conditions with a strip of 'rolling road'.

Hand carving of tyres is a technique that comes in handy during tyre development - a member of the media got to experience the process of carving a tyre

We also had the opportunity to visit Continental's Tyre Carving lab, where tyres are grooved by hand or robots. You might be wondering about the relevance of such a practice, as tyres are now manufactured with machines. The reason is simple - in instances such as during tyre development, tyre tread design is still being altered incrementally, and manufacturing a mould for each prototyping stage would be costly and time consuming, hence carving by hand is still the more effective choice.

The Contidrom is Continental's centre for tyre testing - it is home to unique test facilities and tracks that the brand uses for tyre development

Contidrom - where the tyres are put to the test on the blacktop

While the testing procedures at the R&D Centre are mainly objective, data driven ones, we all know that objective data only accounts for part of the story. Which is why Continental has its own cluster of test tracks within its Contidrom facility.

While objective data could be measured and recorded while a car is driven on the test tracks, such testing would also allow the drivers to make their own subjective impressions on the tyres that are being tested.

Being the centre for tyre testing, the Contidrom consists of various test tracks and facilities, including a dry handling course, wet handling course, various comfort test tracks, a driving simulator facility and the brand's proprietary AIBA (Automated Indoor Braking Analyzer).

Braking tests - AIBA and Wet Braking tests

The AIBA at Contidrom is specially designed for repeatable and consistent testing conditions. This fully-automated tyre braking test facility is used for braking tests on all kinds of surfaces - wet, dry and even on ice.

In the AIBA, the rail-guided cars are accelerated to speeds up to 120km/h and braked on a 75m long braking track. The cars are accelerated with an electromagnetic linear drive, hence you won't find a long and extensive track for acceleration, and there won't be any exhaust fumes within the facility as well. A new addition to the facility is Continental's new Analytical Vehicle AIBA (AVA), a specially designed platform that allows versatile testing. For example, it is even possible to equip one side of this special vehicle with a 16-inch tyre and the opposing side with a 22-inch tyre without issue.

A traditional braking test uses GPS and other telemetry devices to measure braking distance, but human error is still present as the driver controls the speed and braking force of the car

We also got to experience a traditional wet braking test with the new UltraContact UX7 at the ADAC test course earlier on this trip, and it was challenging to ensure that the brake was applied at exactly the same speed on each run. The AIBA facility removes these little discrepancies.

Equipped on exciting cars, the tyres are put to the test at the Dry and Wet Handling Course within Contidrom

Handling tests - Dry and Wet Handling Courses

Continental has a Dry and a Wet Handling course within the Contidrom. The Dry Handling Course is a circuit with a road surface that simulates common dry country roads.

Meanwhile, the Wet Handling Course is a purpose-built 1,800m long track that is consistently and perpetually wet with an even layer of water. The Wet Handling Course is used to test tyre performance in the wet, allowing the team to determine the aquaplaning resistance and cornering performance on such a terrain.

On this visit, we got to drive on the Dry Handling Course (albeit in the wet as it was raining - once again proving the benefits of the indoor AIBA facility), with some amazing cars including the Audi RS3, BMW M3 and Mercedes-AMG C63S on Continental SportContact 7 tyres. The windy course that included a good mix of corners with varying radiuses allows us to push the cars and tyres and explore how they feel when driven hard.

Naturally, the trained test drivers would be able to garner much more information when driving on the track - data can be collected with equipment, measuring g-forces, lap times, etc, while the driver will also be able to give feedback about how the tyre feels, and their breakaway characteristics when pushed past the limits.

The Wet Handling Course is a technical and short course. Being perpetually wet, the friction level is low, and it is used in a similar fashion as the Dry Handling Course. We got to drive the Golf GTI on the MaxContact MC7 tyres for this segment.

Comfort - acoustic and mechanical comfort testing

Unless it's purely for race use, grip and handling isn't everything - you'll want comfort in your daily drive. Tyre noise and damping are all important factors to consider during the design and testing of tyres.

To test the comfort properties of the tyres, the Contidrom has various dedicated roads within that are paved with materials found all over the world. It also has various features such as manhole covers and uneven road surfaces that could be used to test the noise and comfort levels of each tyre. Once again, the comfort testing includes both objective data collection using sensors, as well as subjective ones by test drivers.

A demonstration was done where two tyres emitting the same level of driveby noise were compared, and us as bystanders unanimously decided that the first one was much more pleasant to the ears. This was an example where a subjective test managed to point out a difference that would otherwise be missed by a decibel test, proving the importance of testing outside of rigid data collection.

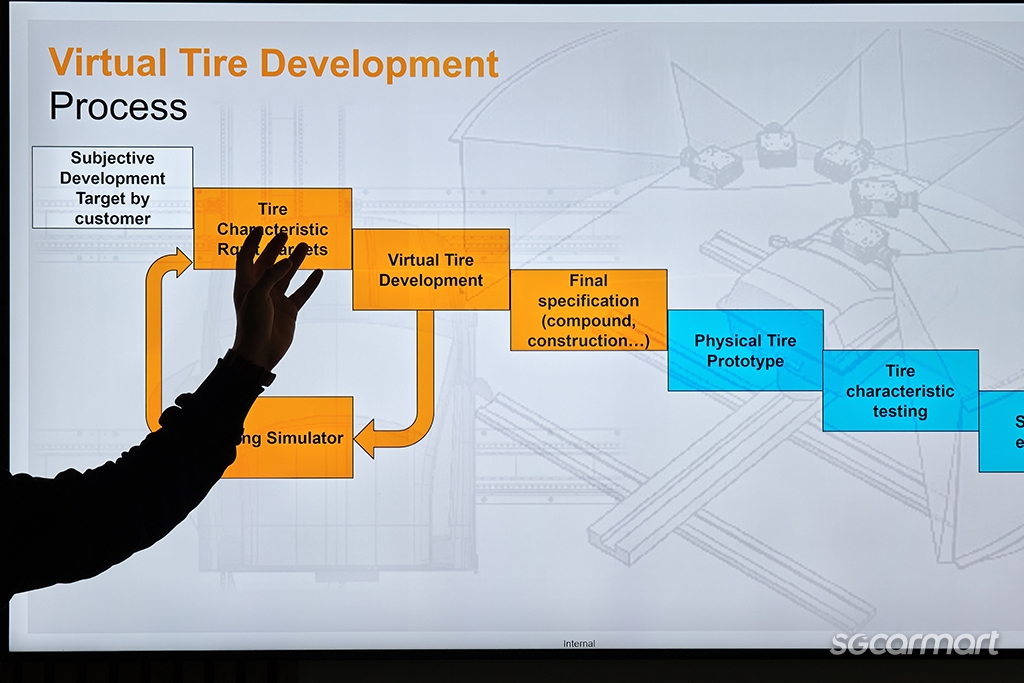

The next-generation of testing procedures – virtual tyre development

On top of traditional testing methods, Continental Tires is also using a high-tech driving simulator that allows virtual tyre testing. What this means is that the engineers can design a tyre virtually, and allow a test driver to test the tyre on the simulator, all without creating an actual physical tyre.

By doing so, developmental time and costs can be lowered, resulting in a shorter, quicker development loop. In the past, prototype tyres will have to be crafted in order for the design to be tested, it then needs to go back to the drawing board to be tweaked and improved, and the cycle continues.

Engineering, making, and testing tyres aren't simple

From this media experience, I have learnt interesting things about the process of creating tyres. I never knew that tyres were X-rayed during development; this was also the first time I've set foot within an indoor tyre testing facility with all the interesting machines.

Continental Tires has given us the rare opportunity for a close look at its processes. And I'm not only impressed by the thorough effort in creating these tyres for our cars, I now also have a higher level of admiration and confidence in the tyres from the brand - after reading about my experience, I'm certain that you would share the same sentiments.

We were invited to Hannover to experience Continental Tires' latest SUV-specific UltraContact UX7 tyres. As part of the programme, the brand curated a two-day itinerary for us to visit its research and development facility and its Contidrom test facility to learn more about how tyres are engineered and tested.

Tyres might seem much simpler than other components of a car, such as the engine or electrical components, but the development and testing process sure isn't simple.

A visit to the home of Continental's designers and engineers

While I've visited the Contidrom facility just last year, this was the first time that I've been invited to visit Continental's R&D Centre. The R&D Centre is home to a team of thousands of researchers, designers and engineers from all over the world, who develop and test the brand's products.

At Continental's R&D Centre, we got to visit several workshops and labs - sadly, photos and videos aren't allowed within most of these facilities.

An interesting one was the Non-Destructive Testing Tire Analysis lab. Over here, X-Ray Computer Tomography (CT Scans) are used to analyse tyres during the development process. This method allows the engineers to get a better understanding of what's happening to the construction of the tyre in various situations (i.e. compressing the tyre against a sharp edge and scanning it), and it can also be used to evaluate manufacturing processes of tyres.

Continental also has an Indoor Testing lab where tyre characteristics such as rolling resistance, static footprint, and static stiffness of the tyre are evaluated. There is also have a costly Flat Trac machine, which allows dynamic testing of tyres - the machine emulates actual driving conditions with a strip of 'rolling road'.

Hand carving of tyres is a technique that comes in handy during tyre development - a member of the media got to experience the process of carving a tyre

We also had the opportunity to visit Continental's Tyre Carving lab, where tyres are grooved by hand or robots. You might be wondering about the relevance of such a practice, as tyres are now manufactured with machines. The reason is simple - in instances such as during tyre development, tyre tread design is still being altered incrementally, and manufacturing a mould for each prototyping stage would be costly and time consuming, hence carving by hand is still the more effective choice.

The Contidrom is Continental's centre for tyre testing - it is home to unique test facilities and tracks that the brand uses for tyre development

Contidrom - where the tyres are put to the test on the blacktop

While the testing procedures at the R&D Centre are mainly objective, data driven ones, we all know that objective data only accounts for part of the story. Which is why Continental has its own cluster of test tracks within its Contidrom facility.

While objective data could be measured and recorded while a car is driven on the test tracks, such testing would also allow the drivers to make their own subjective impressions on the tyres that are being tested.

Being the centre for tyre testing, the Contidrom consists of various test tracks and facilities, including a dry handling course, wet handling course, various comfort test tracks, a driving simulator facility and the brand's proprietary AIBA (Automated Indoor Braking Analyzer).

Braking tests - AIBA and Wet Braking tests

The AIBA at Contidrom is specially designed for repeatable and consistent testing conditions. This fully-automated tyre braking test facility is used for braking tests on all kinds of surfaces - wet, dry and even on ice.

In the AIBA, the rail-guided cars are accelerated to speeds up to 120km/h and braked on a 75m long braking track. The cars are accelerated with an electromagnetic linear drive, hence you won't find a long and extensive track for acceleration, and there won't be any exhaust fumes within the facility as well. A new addition to the facility is Continental's new Analytical Vehicle AIBA (AVA), a specially designed platform that allows versatile testing. For example, it is even possible to equip one side of this special vehicle with a 16-inch tyre and the opposing side with a 22-inch tyre without issue.

A traditional braking test uses GPS and other telemetry devices to measure braking distance, but human error is still present as the driver controls the speed and braking force of the car

We also got to experience a traditional wet braking test with the new UltraContact UX7 at the ADAC test course earlier on this trip, and it was challenging to ensure that the brake was applied at exactly the same speed on each run. The AIBA facility removes these little discrepancies.

Equipped on exciting cars, the tyres are put to the test at the Dry and Wet Handling Course within Contidrom

Handling tests - Dry and Wet Handling Courses

Continental has a Dry and a Wet Handling course within the Contidrom. The Dry Handling Course is a circuit with a road surface that simulates common dry country roads.

Meanwhile, the Wet Handling Course is a purpose-built 1,800m long track that is consistently and perpetually wet with an even layer of water. The Wet Handling Course is used to test tyre performance in the wet, allowing the team to determine the aquaplaning resistance and cornering performance on such a terrain.

On this visit, we got to drive on the Dry Handling Course (albeit in the wet as it was raining - once again proving the benefits of the indoor AIBA facility), with some amazing cars including the Audi RS3, BMW M3 and Mercedes-AMG C63S on Continental SportContact 7 tyres. The windy course that included a good mix of corners with varying radiuses allows us to push the cars and tyres and explore how they feel when driven hard.

Naturally, the trained test drivers would be able to garner much more information when driving on the track - data can be collected with equipment, measuring g-forces, lap times, etc, while the driver will also be able to give feedback about how the tyre feels, and their breakaway characteristics when pushed past the limits.

The Wet Handling Course is a technical and short course. Being perpetually wet, the friction level is low, and it is used in a similar fashion as the Dry Handling Course. We got to drive the Golf GTI on the MaxContact MC7 tyres for this segment.

Comfort - acoustic and mechanical comfort testing

Unless it's purely for race use, grip and handling isn't everything - you'll want comfort in your daily drive. Tyre noise and damping are all important factors to consider during the design and testing of tyres.

To test the comfort properties of the tyres, the Contidrom has various dedicated roads within that are paved with materials found all over the world. It also has various features such as manhole covers and uneven road surfaces that could be used to test the noise and comfort levels of each tyre. Once again, the comfort testing includes both objective data collection using sensors, as well as subjective ones by test drivers.

A demonstration was done where two tyres emitting the same level of driveby noise were compared, and us as bystanders unanimously decided that the first one was much more pleasant to the ears. This was an example where a subjective test managed to point out a difference that would otherwise be missed by a decibel test, proving the importance of testing outside of rigid data collection.

The next-generation of testing procedures – virtual tyre development

On top of traditional testing methods, Continental Tires is also using a high-tech driving simulator that allows virtual tyre testing. What this means is that the engineers can design a tyre virtually, and allow a test driver to test the tyre on the simulator, all without creating an actual physical tyre.

By doing so, developmental time and costs can be lowered, resulting in a shorter, quicker development loop. In the past, prototype tyres will have to be crafted in order for the design to be tested, it then needs to go back to the drawing board to be tweaked and improved, and the cycle continues.

Engineering, making, and testing tyres aren't simple

From this media experience, I have learnt interesting things about the process of creating tyres. I never knew that tyres were X-rayed during development; this was also the first time I've set foot within an indoor tyre testing facility with all the interesting machines.

Continental Tires has given us the rare opportunity for a close look at its processes. And I'm not only impressed by the thorough effort in creating these tyres for our cars, I now also have a higher level of admiration and confidence in the tyres from the brand - after reading about my experience, I'm certain that you would share the same sentiments.

Thank You For Your Subscription.