Not just Neue Klasse cars: BMW readies new class of factory

19 Sep 2025|223 views

Better quality cars - made faster, more flexibly and more sustainably. That seems to be the promise that BMW is spelling out to buyers now, as it readies its latest plant for series production next month. Tagged along to it, inextricably, is thus also the big theoretical question: How do buyers stand to gain?

The all-new BMW iX3 has already been unveiled in full to the world, bringing with it levels of technology not seen before on past models from the brand. Fittingly, BMW has given the revolutionary new generation of cars now set to follow in the taillights of the iX3 a grand label too: The new Neue Klasse.

But beyond the cars themselves, one gets the sense that BMW could also refer to its gleaming new production site as a new class of factory.

BMW is making two huge leaps with its new Neue Klasse - by building an entirely new car at an entirely new plant

Plant Debrecen, a 400-hectare site situated within the suburban industrial zone of Hungary's second-largest city, is the first to leverage the full might of its latest strategy for car production. Dubbed 'BMW iFACTORY', the term refers to a new 'holistic manufacturing concept' built on "efficiency, sustainability and digitalisation for future-proof car production".

Think of the latter not just in terms of cars that stand the test of time in terms of cutting-edge electric powertrains and onboard tech.

Between the lingering embers of a global pandemic, the still-raging fires of an ongoing trade war, and the unstoppable rise of fleet-footed fresh names in the industry, automotive players that can quickly adapt to fast-changing market conditions are ultimately in best stead to maintain quality and speed of production.

It is precisely this sort of higher ground on which BMW appears to be staking a massive bet.

Efficiency and quality baked into every facet of production

Rooted in the principle of next-generation lean manufacturing, efficiency, heightened quality, and production resilience are the cornerstones of Plant Debrecen, which BMW is heralding as a sort of greatest hits album of its very best manufacturing practices.

The ostensible benefit? Cars that aren't just put together more quickly, but are also far less prone to defects (if any at all), and can potentially reach their new owners on tighter timelines.

To arrive at this point, BMW has embraced digitalisation like never before. Series production of the iX3 will begin officially in end-October, but back in March 2023, the site had already celebrated its "digital opening". Imagine a factory in full-blown production - just in the virtual sphere - during which BMW fastidiously simulated every conceivable facet from the building structures to the varied production processes, before all 400 hectares of Plant Debrecen had materialised in concrete, metal and glass.

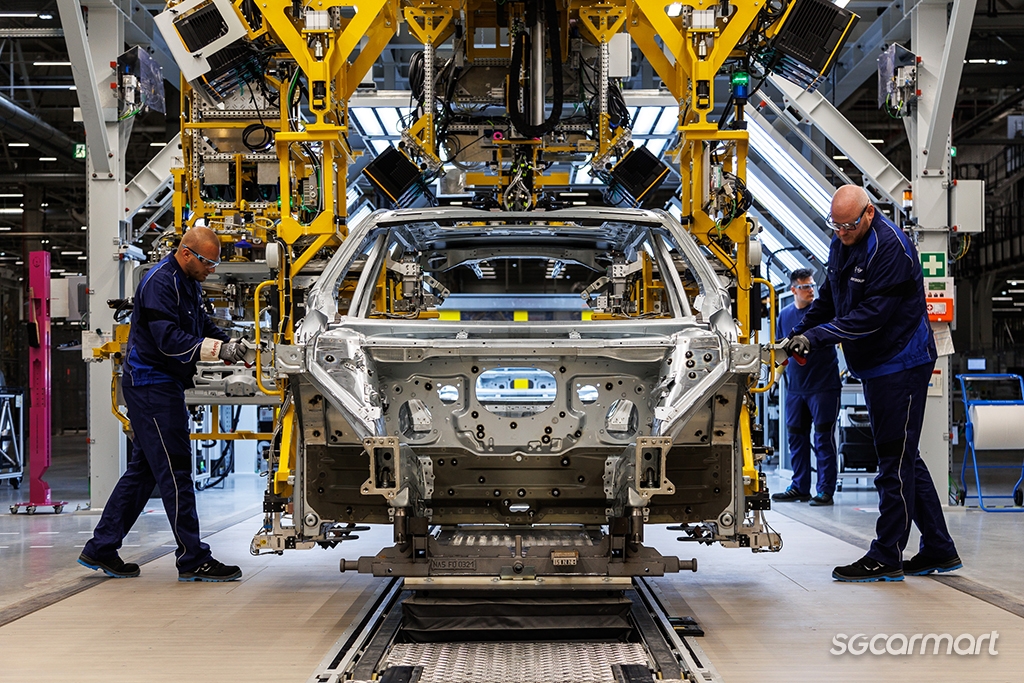

Extensive simulations beforehand helped BMW to ascertain the ideal value streams in the body shop, and even determine where its nearly 1,000-strong army of robots should be positioned

The result is a physical facility today that doesn't just boast an ideal layout, but also contains the most optimised manufacturing methods ever employed by the brand.

The simulations enabled it to ascertain - for instance - what the ideal value streams for the plant's body shop were, as well as determine where its nearly 1,000 robots should be positioned. In essence, visualise the fundamental structure of your new iX3 coming together more quickly than any other electric BMW before it.

Plant Debrecen is also BMW Group's first facility that assembles its its Gen6 high-voltage batteries onsite

Elsewhere, Debrecen marks the pioneering site at which BMW is developing its Gen6 high-voltage batteries for the Neue Klasse cars (four more battery assembly plants are set to follow worldwide). Once more, production resilience against external factors is expected to be bolstered, given its close proximity to all the other plants responsible for the iX3's assembly.

BMW is putting production efficiency on such a high pedestal that its efforts are even evident in the componentry of the new Neue Klasse cars. Close collaboration between the development and production means the iX3 is - surprisingly - less complex to manufacture than its forebears, despite it boasting significant leaps in technology and range over past BMW BEVs.

The car's new-generation "zonal" wiring harness system, which is divided into four separate zones as opposed to the fully-interconnected iteration it succeeds, is a clear example. It's not only 30% lighter, but also requires 600 fewer metres of wiring, facilitating easier installation. The new modularisation of components within the iX3 also reduces the variation of connecting elements to simplify - and accelerate - the assembly process.

In the present, digitalisation also continues to be weaponised for another factor that should resonate strongly with those already eager to buy an iX3: Quality control.

BMW is also leaning heavily on digitalisation and AI in its pursuit of a zero-defect manufacturing goal at Plant Debrecen

A new in-house developed IT platform called AIQX (Artificial Intelligence Quality Next) relies on sensors and camera systems to evaluate data and provide feedback in real-time - with AI-assistance - to employees working on the production line. It can simultaneously conduct digital quality checks.

And unsurprisingly, AIQX is also capable of keeping perhaps the most crucial tool in this entire equation in check: Itself. With this, BMW believes that maintenance intervals (within the factory) will be eliminated almost entirely moving forward, since the system can flag issues up to staff on its own. The end point to all this? A production ecosystem that promises minimal defects.

Future-proofing in a world with finite resources

Advancements in technology aside, Debrecen also fleshes BMW's sustainability ambitions out in full. Against a looming backdrop of ever-tightening emissions regulations - and car buyers should know that this applies even on the production front - such efforts evince the brand's determination to remain in the business of producing cars for decades to come.

Plant Debrecen is the first BMW Group car plant to be fully dependent on electricity from renewable energy during normal operation. The weather in Debrecen is on the sunnier end for continental Europe, and here, 50 hectares worth of photovoltaic panels are responsible for up to a quarter of the plant's energy needs, with the remainder coming from renewable sources within the region (such as wind farms).

Electrification has taken hold of the site thoroughly too - and not just with the full-electric in-house logistics fleet running around on the factory floors.

The plant also hosts the world's first fully electrified paint shop - a crucial piece of its larger carbon-neutral puzzle, considering that paint shops are typically the most energy-intensive of any factory

One of Plant Debrecen's undeniable green highlights is its paint shop, which BMW is claiming to be the first in the automotive world to be fully electrified, and for which it has filed patents and made significant investments. Considering that paint shops typically make up some of the most carbon-intensive parts of a production plant, BMW estimates that this decision enables it to reduce up to 12,000 tonnes of CO2 emissions annually.

The average iX3-buyer may still not see the car's lifecycle emissions as a factor that will influence their purchase, but the stark reality remains: Our planet is resource-constrained. Beyond the corporate talk of aligning itself with the Paris Agreement, its decision to fully embrace a carbon-neutral facility represents yet another effort to future-proof production for the decades to come.

Next-era car, next-era carmaking, next era for BMW

At its most fundamental level, then, what Plant Debrecen is now inviting consumers to ask is not just a question of what BMW is building, but how it's doing it.

There should be no doubt already that the advancements seen here promise electric cars of the highest quality seen from BMW yet. Theoretically, however, another golden egg often associated with lean manufacturing is a reduction in production costs.

Whether or not these will be passed on to consumers is a tougher question to answer - especially since substantial investment preceded BMW's ability to now christen Plant Debrecen as its greenest, smartest and most efficient plant yet. Still, the fact that the new iX3's pricing is effectively level with that of the outgoing car strongly signals an intent to allow end-users to benefit.

Production volume of the iX3 at Plant Debrecen will also be ramped up in phases, but just as crucially, its flexible setup will allow it to eventually welcome production of other Neue Klasse models in the future.

Furthermore, lessons gleaned from the sparkling production floors here are already being transferred to other sites globally. The brand has already confirmed that its bestselling 3 Series model line will gain an all-electric successor in the form of the i3 sedan by end-2026, with Plant Munich - located right next to the Group's headquarters - earmarked for its production.

And from a pure-numbers standpoint, Debrecen also stands as a loud vote of faith in the company's continued growth.

The site is expected to have a production capacity of 150,000 cars annually when operations are fully maxed out. While that's more than one-third of the 426,594 of battery-electric vehicle models delivered by the BMW Group (inclusive of MINI) last year, the Group expects BEV sales will still grow, as more drivers become attuned to the joys of going electric.

As they say, however, the proof of the pudding is ultimately in the eating, and BMW fans eagerly tracking the brand's latest developments won't need to bear with an extended wait to experience what Plant Debrecen is promising.

The iX3 is slated for market launch between end-2025 and early-2026 (Singaporeans can expect it between Q2 and Q3 2026). Thereafter, BMW has laid out an ambitious roadmap to roll out 40 new and updated models by 2027 that will use it as their technological template.

Not all of them will be mechanically similar to the iX3; BMW is still committing to combustion power for the foreseeable future. Still, the promises of elevated efficiency and quality should invariably trickle down through the range. When they do, the new production standards now touted by BMW will be laid bare for the world to judge for themselves.

Ultimately, then, Plant Debrecen holds a crystal-clear mirror up to the iX3 - not just in its embodiment of a new production philosophy for the more-than-30 BMW Group plants around the world, but in its determination to defend its position in the auto industry today. Beyond a new Neue Klasse car, it seems that BMW has also planted the seeds for a new class of factory.

Here are a few other articles that may interest you!

More than sales: Why Singapore matters to BMW

BMW Test Fest Spartanburg: Through space and time

BMW Vision Neue Klasse X: When is a concept car no longer a concept?

Better quality cars - made faster, more flexibly and more sustainably. That seems to be the promise that BMW is spelling out to buyers now, as it readies its latest plant for series production next month. Tagged along to it, inextricably, is thus also the big theoretical question: How do buyers stand to gain?

The all-new BMW iX3 has already been unveiled in full to the world, bringing with it levels of technology not seen before on past models from the brand. Fittingly, BMW has given the revolutionary new generation of cars now set to follow in the taillights of the iX3 a grand label too: The new Neue Klasse.

But beyond the cars themselves, one gets the sense that BMW could also refer to its gleaming new production site as a new class of factory.

BMW is making two huge leaps with its new Neue Klasse - by building an entirely new car at an entirely new plant

Plant Debrecen, a 400-hectare site situated within the suburban industrial zone of Hungary's second-largest city, is the first to leverage the full might of its latest strategy for car production. Dubbed 'BMW iFACTORY', the term refers to a new 'holistic manufacturing concept' built on "efficiency, sustainability and digitalisation for future-proof car production".

Think of the latter not just in terms of cars that stand the test of time in terms of cutting-edge electric powertrains and onboard tech.

Between the lingering embers of a global pandemic, the still-raging fires of an ongoing trade war, and the unstoppable rise of fleet-footed fresh names in the industry, automotive players that can quickly adapt to fast-changing market conditions are ultimately in best stead to maintain quality and speed of production.

It is precisely this sort of higher ground on which BMW appears to be staking a massive bet.

Efficiency and quality baked into every facet of production

Rooted in the principle of next-generation lean manufacturing, efficiency, heightened quality, and production resilience are the cornerstones of Plant Debrecen, which BMW is heralding as a sort of greatest hits album of its very best manufacturing practices.

The ostensible benefit? Cars that aren't just put together more quickly, but are also far less prone to defects (if any at all), and can potentially reach their new owners on tighter timelines.

To arrive at this point, BMW has embraced digitalisation like never before. Series production of the iX3 will begin officially in end-October, but back in March 2023, the site had already celebrated its "digital opening". Imagine a factory in full-blown production - just in the virtual sphere - during which BMW fastidiously simulated every conceivable facet from the building structures to the varied production processes, before all 400 hectares of Plant Debrecen had materialised in concrete, metal and glass.

Extensive simulations beforehand helped BMW to ascertain the ideal value streams in the body shop, and even determine where its nearly 1,000-strong army of robots should be positioned

The result is a physical facility today that doesn't just boast an ideal layout, but also contains the most optimised manufacturing methods ever employed by the brand.

The simulations enabled it to ascertain - for instance - what the ideal value streams for the plant's body shop were, as well as determine where its nearly 1,000 robots should be positioned. In essence, visualise the fundamental structure of your new iX3 coming together more quickly than any other electric BMW before it.

Plant Debrecen is also BMW Group's first facility that assembles its its Gen6 high-voltage batteries onsite

Elsewhere, Debrecen marks the pioneering site at which BMW is developing its Gen6 high-voltage batteries for the Neue Klasse cars (four more battery assembly plants are set to follow worldwide). Once more, production resilience against external factors is expected to be bolstered, given its close proximity to all the other plants responsible for the iX3's assembly.

BMW is putting production efficiency on such a high pedestal that its efforts are even evident in the componentry of the new Neue Klasse cars. Close collaboration between the development and production means the iX3 is - surprisingly - less complex to manufacture than its forebears, despite it boasting significant leaps in technology and range over past BMW BEVs.

The car's new-generation "zonal" wiring harness system, which is divided into four separate zones as opposed to the fully-interconnected iteration it succeeds, is a clear example. It's not only 30% lighter, but also requires 600 fewer metres of wiring, facilitating easier installation. The new modularisation of components within the iX3 also reduces the variation of connecting elements to simplify - and accelerate - the assembly process.

In the present, digitalisation also continues to be weaponised for another factor that should resonate strongly with those already eager to buy an iX3: Quality control.

BMW is also leaning heavily on digitalisation and AI in its pursuit of a zero-defect manufacturing goal at Plant Debrecen

A new in-house developed IT platform called AIQX (Artificial Intelligence Quality Next) relies on sensors and camera systems to evaluate data and provide feedback in real-time - with AI-assistance - to employees working on the production line. It can simultaneously conduct digital quality checks.

And unsurprisingly, AIQX is also capable of keeping perhaps the most crucial tool in this entire equation in check: Itself. With this, BMW believes that maintenance intervals (within the factory) will be eliminated almost entirely moving forward, since the system can flag issues up to staff on its own. The end point to all this? A production ecosystem that promises minimal defects.

Future-proofing in a world with finite resources

Advancements in technology aside, Debrecen also fleshes BMW's sustainability ambitions out in full. Against a looming backdrop of ever-tightening emissions regulations - and car buyers should know that this applies even on the production front - such efforts evince the brand's determination to remain in the business of producing cars for decades to come.

Plant Debrecen is the first BMW Group car plant to be fully dependent on electricity from renewable energy during normal operation. The weather in Debrecen is on the sunnier end for continental Europe, and here, 50 hectares worth of photovoltaic panels are responsible for up to a quarter of the plant's energy needs, with the remainder coming from renewable sources within the region (such as wind farms).

Electrification has taken hold of the site thoroughly too - and not just with the full-electric in-house logistics fleet running around on the factory floors.

The plant also hosts the world's first fully electrified paint shop - a crucial piece of its larger carbon-neutral puzzle, considering that paint shops are typically the most energy-intensive of any factory

One of Plant Debrecen's undeniable green highlights is its paint shop, which BMW is claiming to be the first in the automotive world to be fully electrified, and for which it has filed patents and made significant investments. Considering that paint shops typically make up some of the most carbon-intensive parts of a production plant, BMW estimates that this decision enables it to reduce up to 12,000 tonnes of CO2 emissions annually.

The average iX3-buyer may still not see the car's lifecycle emissions as a factor that will influence their purchase, but the stark reality remains: Our planet is resource-constrained. Beyond the corporate talk of aligning itself with the Paris Agreement, its decision to fully embrace a carbon-neutral facility represents yet another effort to future-proof production for the decades to come.

Next-era car, next-era carmaking, next era for BMW

At its most fundamental level, then, what Plant Debrecen is now inviting consumers to ask is not just a question of what BMW is building, but how it's doing it.

There should be no doubt already that the advancements seen here promise electric cars of the highest quality seen from BMW yet. Theoretically, however, another golden egg often associated with lean manufacturing is a reduction in production costs.

Whether or not these will be passed on to consumers is a tougher question to answer - especially since substantial investment preceded BMW's ability to now christen Plant Debrecen as its greenest, smartest and most efficient plant yet. Still, the fact that the new iX3's pricing is effectively level with that of the outgoing car strongly signals an intent to allow end-users to benefit.

Production volume of the iX3 at Plant Debrecen will also be ramped up in phases, but just as crucially, its flexible setup will allow it to eventually welcome production of other Neue Klasse models in the future.

Furthermore, lessons gleaned from the sparkling production floors here are already being transferred to other sites globally. The brand has already confirmed that its bestselling 3 Series model line will gain an all-electric successor in the form of the i3 sedan by end-2026, with Plant Munich - located right next to the Group's headquarters - earmarked for its production.

And from a pure-numbers standpoint, Debrecen also stands as a loud vote of faith in the company's continued growth.

The site is expected to have a production capacity of 150,000 cars annually when operations are fully maxed out. While that's more than one-third of the 426,594 of battery-electric vehicle models delivered by the BMW Group (inclusive of MINI) last year, the Group expects BEV sales will still grow, as more drivers become attuned to the joys of going electric.

As they say, however, the proof of the pudding is ultimately in the eating, and BMW fans eagerly tracking the brand's latest developments won't need to bear with an extended wait to experience what Plant Debrecen is promising.

The iX3 is slated for market launch between end-2025 and early-2026 (Singaporeans can expect it between Q2 and Q3 2026). Thereafter, BMW has laid out an ambitious roadmap to roll out 40 new and updated models by 2027 that will use it as their technological template.

Not all of them will be mechanically similar to the iX3; BMW is still committing to combustion power for the foreseeable future. Still, the promises of elevated efficiency and quality should invariably trickle down through the range. When they do, the new production standards now touted by BMW will be laid bare for the world to judge for themselves.

Ultimately, then, Plant Debrecen holds a crystal-clear mirror up to the iX3 - not just in its embodiment of a new production philosophy for the more-than-30 BMW Group plants around the world, but in its determination to defend its position in the auto industry today. Beyond a new Neue Klasse car, it seems that BMW has also planted the seeds for a new class of factory.

Here are a few other articles that may interest you!

More than sales: Why Singapore matters to BMW

BMW Test Fest Spartanburg: Through space and time

BMW Vision Neue Klasse X: When is a concept car no longer a concept?

Thank You For Your Subscription.