New virtual reality design evaluation system for Hyundai Group

19 Dec 2019|938 views

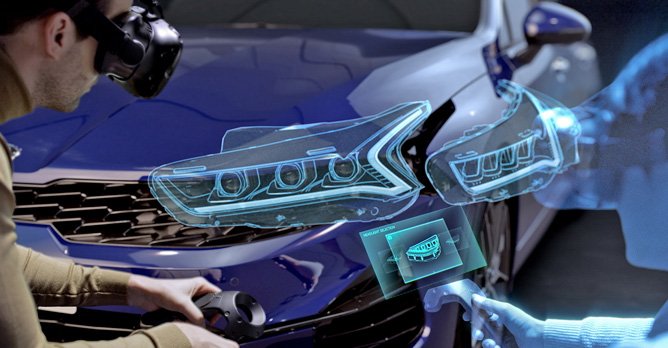

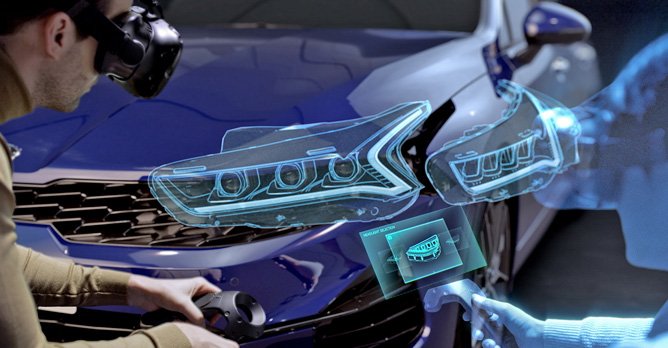

Kia Motors Corporation and the Hyundai Motor Company have debuted a new Virtual Reality (VR) design evaluation system at the brands' global design headquarters.

The technology uses several development applications, enabling teams of designers and engineers to carry out vehicle design quality assessments and development verification processes, and is part of the $17.4 million investment in the Namyang Research and Development Centre announced by Kia and Hyundai in March 2019.

VR headsets allow the brands' vehicle designers and engineers to virtually enter developmental simulations, with 36 motion tracking sensors detecting and tracking the locations and movement of all users, enabling each to participate accurately in real time. The new VR design evaluation system can currently support up to 20 simultaneous users, enabling greater cross-team collaboration than ever before.

Where previous quality verification processes began with the manufacturing of a test vehicle, this process can now be accomplished virtually, during the pre-production stage.

Quality verification using virtual models and techniques in early design stages will ultimately enhance the quality control of real-world vehicles.

Through the complete implementation of the virtual development processes throughout research and development and pre-production stages, Kia and Hyundai anticipates a 20% reduction in vehicle development times and a 15% reduction in annual development costs.

Kia Motors Corporation and the Hyundai Motor Company have debuted a new Virtual Reality (VR) design evaluation system at the brands' global design headquarters.

The technology uses several development applications, enabling teams of designers and engineers to carry out vehicle design quality assessments and development verification processes, and is part of the $17.4 million investment in the Namyang Research and Development Centre announced by Kia and Hyundai in March 2019.

VR headsets allow the brands' vehicle designers and engineers to virtually enter developmental simulations, with 36 motion tracking sensors detecting and tracking the locations and movement of all users, enabling each to participate accurately in real time. The new VR design evaluation system can currently support up to 20 simultaneous users, enabling greater cross-team collaboration than ever before.

Where previous quality verification processes began with the manufacturing of a test vehicle, this process can now be accomplished virtually, during the pre-production stage.

Quality verification using virtual models and techniques in early design stages will ultimately enhance the quality control of real-world vehicles.

Through the complete implementation of the virtual development processes throughout research and development and pre-production stages, Kia and Hyundai anticipates a 20% reduction in vehicle development times and a 15% reduction in annual development costs.

Latest COE Prices

May 2025 | 1st BIDDING

NEXT TENDER: 21 May 2025

CAT A$103,009

CAT B$119,890

CAT C$62,590

CAT E$118,889

View Full Results Thank You For Your Subscription.