Nissan develops advanced sulev-standard clean diesel

11 Aug 2007|3,388 views

Nissan Motor Co., Ltd. today announced that a new clean diesel technology using high-performance catalysts shows great promise and may be able to meet the State of California's standard for super-ultra-low emission vehicles (SULEVs), equivalent to the Tier2Bin2 emissions requirements. Nissan plans to do further research and development of the clean diesel technology for commercial application in its future products.

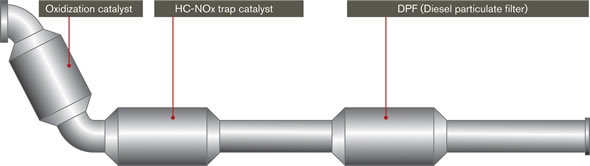

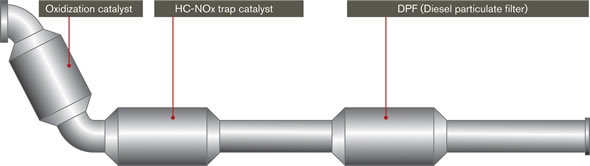

Nissan Motor Co., Ltd. today announced that a new clean diesel technology using high-performance catalysts shows great promise and may be able to meet the State of California's standard for super-ultra-low emission vehicles (SULEVs), equivalent to the Tier2Bin2 emissions requirements. Nissan plans to do further research and development of the clean diesel technology for commercial application in its future products. Three components work together in Nissan's new technology to reduce diesel emissions: modulated-kinetic (MK) combustion*, high-performance catalysts, and advanced engine control systems*.

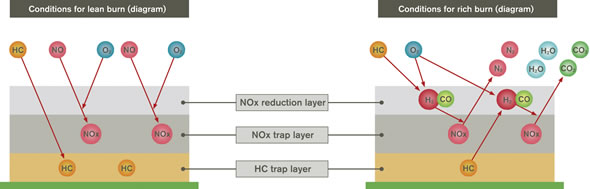

Nissan's unique Hydrocarbon-Oxides of Nitrogen (HC-NOx) trap catalyst technology comprise a breakthrough construction which incorporates a HC-trap layer in the NOx-trap catalyst. The HC-trap layer serves to trap the HC which is oxidized to generate hydrogen (H2) and carbon monoxide (CO), which in turn react with the NOx gases trapped by the NOx-trap layer to produce nitrogen (N2) and carbon dioxide (CO2) gases, in addition to water vapor (H2O) as end products. The chemical reactions effectively reduce HC and NOx resulting in cleaner tail-pipe emissions.

The company had previously announced clean diesel technology that met the U.S. Tier2Bin5 emissions standards. With this new HC-NOx trap catalyst technology, Nissan believes it will be able to achieve cleaner diesel emissions in future vehicles that will meet the stringent SULEV-standards set by the state of California. In order to meet the SULEV-standards, hydrocarbons in vehicle emissions must be exhaust reduced by about 90% and NOx levels must be reduced by 70%* versus Tier2Bin5 standards.

Under the Nissan Green Program 2010, Nissan has announced plans to expand clean diesels to surpass current emission standards. Looking ahead, stricter regulations will be imposed in major markets including Japan, US, and Europe within the next few years.

| Structure of the HC-NOx-trap catalyst and emission control system | ||||||

| ||||||

|

Nissan Motor Co., Ltd. today announced that a new clean diesel technology using high-performance catalysts shows great promise and may be able to meet the State of California's standard for super-ultra-low emission vehicles (SULEVs), equivalent to the Tier2Bin2 emissions requirements. Nissan plans to do further research and development of the clean diesel technology for commercial application in its future products.

Nissan Motor Co., Ltd. today announced that a new clean diesel technology using high-performance catalysts shows great promise and may be able to meet the State of California's standard for super-ultra-low emission vehicles (SULEVs), equivalent to the Tier2Bin2 emissions requirements. Nissan plans to do further research and development of the clean diesel technology for commercial application in its future products. Three components work together in Nissan's new technology to reduce diesel emissions: modulated-kinetic (MK) combustion*, high-performance catalysts, and advanced engine control systems*.

Nissan's unique Hydrocarbon-Oxides of Nitrogen (HC-NOx) trap catalyst technology comprise a breakthrough construction which incorporates a HC-trap layer in the NOx-trap catalyst. The HC-trap layer serves to trap the HC which is oxidized to generate hydrogen (H2) and carbon monoxide (CO), which in turn react with the NOx gases trapped by the NOx-trap layer to produce nitrogen (N2) and carbon dioxide (CO2) gases, in addition to water vapor (H2O) as end products. The chemical reactions effectively reduce HC and NOx resulting in cleaner tail-pipe emissions.

The company had previously announced clean diesel technology that met the U.S. Tier2Bin5 emissions standards. With this new HC-NOx trap catalyst technology, Nissan believes it will be able to achieve cleaner diesel emissions in future vehicles that will meet the stringent SULEV-standards set by the state of California. In order to meet the SULEV-standards, hydrocarbons in vehicle emissions must be exhaust reduced by about 90% and NOx levels must be reduced by 70%* versus Tier2Bin5 standards.

Under the Nissan Green Program 2010, Nissan has announced plans to expand clean diesels to surpass current emission standards. Looking ahead, stricter regulations will be imposed in major markets including Japan, US, and Europe within the next few years.

| Structure of HC-NOx-trap catalyst and NOx reduction image | |||||||

| |||||||

|

| ||||||

| Structure of the HC-NOx-trap catalyst and emission control system | ||||||

| ||||||

|

Latest COE Prices

January 2026 | 2nd BIDDING

NEXT TENDER: 04 Feb 2026

CAT A$109,501

CAT B$121,634

CAT C$75,202

CAT E$120,891

View Full Results Thank You For Your Subscription.