Fiat's new camshaft technology promises more power for less fuel

09 Mar 2009|5,173 views

|

The new technology claims that maximum power will be increased by up to 10 percent, while low rpm torque goes up by up to 15 percent. Apart from also being able to achieve greater fuel economy and reduce harmful gas emissions, the MultiAir design is applicable to all internal combustion engines, regardless of the type of fuel used.

In short, an engine equipped with Fiat MultiAir technology is more powerful, more responsive across the entire engine speed range, uses considerably less fuel, and reduces all types of exhaust emissions by a substantial amount. It will also assist in enabling Fiat to maintain its lead in low emissions and low fuel consumption technology, which has seen Fiat crowned for the past two years as the number one car maker for the lowest range-wide CO2 emissions.

The first new engine to be equipped with MultiAir will be the 16-valve 1.4 litre family of naturally aspirated and turbocharged engines, and the first car to go on sale with MultiAir installed will be the Alfa MiTo at the end of 2009. Its second application will be as an integral part of a new two cylinder engine family.

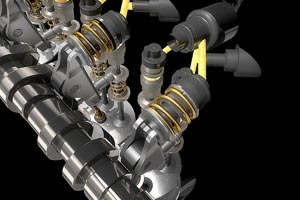

MultiAir Technology: How it works

The operating principle of the system, applied to intake valves, is the following: a piston, moved by a mechanical intake camshaft, is connected to the intake valve through a hydraulic chamber, which is controlled by a normally open on/off solenoid valve.

When the solenoid valve is closed, the oil in the hydraulic chamber behaves like a solid body and transmits to the intake valves the lift schedule imposed by the mechanical intake camshaft.

When the solenoid valve is open, the hydraulic chamber and the intake valves are de-coupled; the intake valves do not follow the intake camshaft anymore and close under the valve spring action.

The final part of the valve closing stroke is controlled by a dedicated hydraulic brake, to ensure a soft and regular landing phase in any engine operating conditions.

Through solenoid valve opening and closing time control, a wide range of optimum intake valve opening schedules can be easily obtained.

For maximum power, the solenoid valve is always closed and full valve opening is achieved following completely the mechanical camshaft, which is specifically designed to maximise power at high engine speed (long opening time).

For low-rpm torque, the solenoid valve is opened near the end of the camshaft profile, leading to early intake valve closing. This eliminates unwanted backflow into the manifold and maximises the air mass trapped in the cylinders.

In engine part-load, the solenoid valve is opened earlier, causing partial valve openings to control the trapped air mass as a function of the required torque.

Alternatively the intake valves can be partially opened by closing the solenoid valve once the mechanical camshaft action has already started. In this case the air stream into the cylinder is faster and results in higher in-cylinder turbulence.

The last two actuation modes can be combined in the same intake stroke, generating a so-called Multilift mode that enhances turbulence and combustion rate at very low loads.

|

The new technology claims that maximum power will be increased by up to 10 percent, while low rpm torque goes up by up to 15 percent. Apart from also being able to achieve greater fuel economy and reduce harmful gas emissions, the MultiAir design is applicable to all internal combustion engines, regardless of the type of fuel used.

In short, an engine equipped with Fiat MultiAir technology is more powerful, more responsive across the entire engine speed range, uses considerably less fuel, and reduces all types of exhaust emissions by a substantial amount. It will also assist in enabling Fiat to maintain its lead in low emissions and low fuel consumption technology, which has seen Fiat crowned for the past two years as the number one car maker for the lowest range-wide CO2 emissions.

The first new engine to be equipped with MultiAir will be the 16-valve 1.4 litre family of naturally aspirated and turbocharged engines, and the first car to go on sale with MultiAir installed will be the Alfa MiTo at the end of 2009. Its second application will be as an integral part of a new two cylinder engine family.

MultiAir Technology: How it works

The operating principle of the system, applied to intake valves, is the following: a piston, moved by a mechanical intake camshaft, is connected to the intake valve through a hydraulic chamber, which is controlled by a normally open on/off solenoid valve.

When the solenoid valve is closed, the oil in the hydraulic chamber behaves like a solid body and transmits to the intake valves the lift schedule imposed by the mechanical intake camshaft.

When the solenoid valve is open, the hydraulic chamber and the intake valves are de-coupled; the intake valves do not follow the intake camshaft anymore and close under the valve spring action.

The final part of the valve closing stroke is controlled by a dedicated hydraulic brake, to ensure a soft and regular landing phase in any engine operating conditions.

Through solenoid valve opening and closing time control, a wide range of optimum intake valve opening schedules can be easily obtained.

For maximum power, the solenoid valve is always closed and full valve opening is achieved following completely the mechanical camshaft, which is specifically designed to maximise power at high engine speed (long opening time).

For low-rpm torque, the solenoid valve is opened near the end of the camshaft profile, leading to early intake valve closing. This eliminates unwanted backflow into the manifold and maximises the air mass trapped in the cylinders.

In engine part-load, the solenoid valve is opened earlier, causing partial valve openings to control the trapped air mass as a function of the required torque.

Alternatively the intake valves can be partially opened by closing the solenoid valve once the mechanical camshaft action has already started. In this case the air stream into the cylinder is faster and results in higher in-cylinder turbulence.

The last two actuation modes can be combined in the same intake stroke, generating a so-called Multilift mode that enhances turbulence and combustion rate at very low loads.

Latest COE Prices

July 2025 | 2nd BIDDING

NEXT TENDER: 06 Aug 2025

CAT A$101,102

CAT B$119,101

CAT C$68,600

CAT E$120,000

View Full Results Thank You For Your Subscription.