Hyundai and Kia develop new heat pump technology

12 Jun 2020|520 views

Hyundai Motor Company and Kia Motors Corporation have revealed new details of their innovative heat pump system, deployed in Hyundai and Kia's global Electric Vehicle (EV) lineup to maximise all-electric driving range in low temperatures.

Hyundai and Kia's heat pump is a leading heat management innovation that maximises the distance that Hyundai and Kia EVs can travel on a single charge, scavenging waste heat to warm the cabin.

It enables EV drivers to heat their car's cabin in cold weather without significantly impacting electric driving range, unlike other EVs.

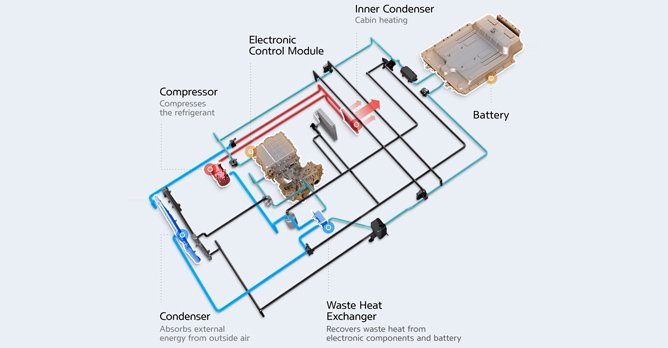

The technology was first introduced in 2014 on the first generation Kia Soul EV. Comprising a compressor, evaporator and condenser, the heat pump captured waste heat given off by the vehicle's electrical components, recycling this energy to heat the cabin more efficiently.

The industry-leading heat pump system has now been developed further for new EVs from Hyundai and Kia. The new system scavenges waste heat from an increased number of sources for optimum cold-weather EV range. These innovations mean that Hyundai and Kia EVs offer more consistent range in temperatures where other EVs start to see a significant decline in the distance possible from a single charge.

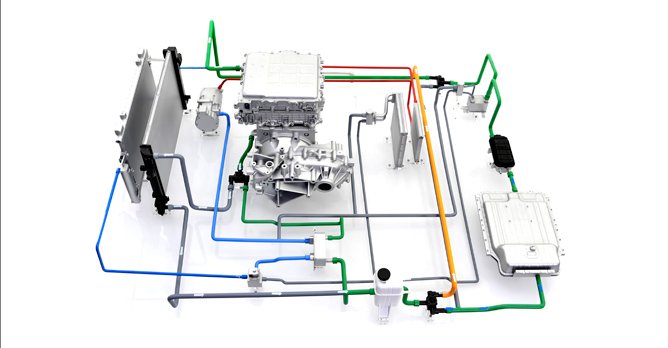

It now harvests significantly more energy by recycling additional waste heat not only from power electrics modules such as drive motors, on-board chargers, and inverters, but also from the battery pack and slow charger.

The system uses the heat generated by these components to vaporise refrigerant from liquid to gas form. This captured energy improves the efficiency of the Heating, Ventilation and Air Conditioning (HVAC) system, recycling it to more efficiently heat up the cabin and minimize battery power consumption.

By reducing the load on the battery, the heat pump cuts energy consumption from the HVAC system, maximizing the available electric driving range of the car.

The heat pump is one of a number of innovations found in Hyundai and Kia's current generation of EVs, with heat management also used to realise major improvements in EV battery packs.

A water-cooling system for Hyundai and Kia's EV battery packs, rather than conventional air cooling, have yielded further increases in range without increasing physical dimensions. This development means battery cells in Hyundai and Kia EVs can be packaged much more tightly, with water-cooling channels taking up less space than air-cooling channels, increasing battery density by up to 35%, which means the latest EVs from Hyundai and Kia offer around twice as much driving range and battery capacity compared to the their first-generation EVs.

A study carried out by Korea's Ministry of the Environment on the Hyundai Kona Electric and Kia Niro EV found that the heat pump significantly reduced battery consumption, maintaining 90% of their driving range at -7°C with the HVAC system activated compared to journeys undertaken at an ambient 26°C.

By contrast, many EVs offered by other manufacturers saw their total electric driving range drop by between 18% and 43% under the same test conditions.

Hyundai and Kia continue to hone and improve the heat pump system and other heat management innovations, with the technologies currently informing the development of next-generation EVs from each brand. Under its 'Strategy 2025' plan, Hyundai Motor aims to sell 670,000 battery EVs and Fuel Cell Electric Vehicles annually and become a top-three EV manufacturer by 2025. Kia's mid to long-term strategy, dubbed 'Plan S', will see the brand's lineup grow to 11 EVs over the same timeframe.

Hyundai Motor Company and Kia Motors Corporation have revealed new details of their innovative heat pump system, deployed in Hyundai and Kia's global Electric Vehicle (EV) lineup to maximise all-electric driving range in low temperatures.

Hyundai and Kia's heat pump is a leading heat management innovation that maximises the distance that Hyundai and Kia EVs can travel on a single charge, scavenging waste heat to warm the cabin.

It enables EV drivers to heat their car's cabin in cold weather without significantly impacting electric driving range, unlike other EVs.

The technology was first introduced in 2014 on the first generation Kia Soul EV. Comprising a compressor, evaporator and condenser, the heat pump captured waste heat given off by the vehicle's electrical components, recycling this energy to heat the cabin more efficiently.

The industry-leading heat pump system has now been developed further for new EVs from Hyundai and Kia. The new system scavenges waste heat from an increased number of sources for optimum cold-weather EV range. These innovations mean that Hyundai and Kia EVs offer more consistent range in temperatures where other EVs start to see a significant decline in the distance possible from a single charge.

It now harvests significantly more energy by recycling additional waste heat not only from power electrics modules such as drive motors, on-board chargers, and inverters, but also from the battery pack and slow charger.

The system uses the heat generated by these components to vaporise refrigerant from liquid to gas form. This captured energy improves the efficiency of the Heating, Ventilation and Air Conditioning (HVAC) system, recycling it to more efficiently heat up the cabin and minimize battery power consumption.

By reducing the load on the battery, the heat pump cuts energy consumption from the HVAC system, maximizing the available electric driving range of the car.

The heat pump is one of a number of innovations found in Hyundai and Kia's current generation of EVs, with heat management also used to realise major improvements in EV battery packs.

A water-cooling system for Hyundai and Kia's EV battery packs, rather than conventional air cooling, have yielded further increases in range without increasing physical dimensions. This development means battery cells in Hyundai and Kia EVs can be packaged much more tightly, with water-cooling channels taking up less space than air-cooling channels, increasing battery density by up to 35%, which means the latest EVs from Hyundai and Kia offer around twice as much driving range and battery capacity compared to the their first-generation EVs.

A study carried out by Korea's Ministry of the Environment on the Hyundai Kona Electric and Kia Niro EV found that the heat pump significantly reduced battery consumption, maintaining 90% of their driving range at -7°C with the HVAC system activated compared to journeys undertaken at an ambient 26°C.

By contrast, many EVs offered by other manufacturers saw their total electric driving range drop by between 18% and 43% under the same test conditions.

Hyundai and Kia continue to hone and improve the heat pump system and other heat management innovations, with the technologies currently informing the development of next-generation EVs from each brand. Under its 'Strategy 2025' plan, Hyundai Motor aims to sell 670,000 battery EVs and Fuel Cell Electric Vehicles annually and become a top-three EV manufacturer by 2025. Kia's mid to long-term strategy, dubbed 'Plan S', will see the brand's lineup grow to 11 EVs over the same timeframe.

Latest COE Prices

May 2025 | 1st BIDDING

NEXT TENDER: 21 May 2025

CAT A$103,009

CAT B$119,890

CAT C$62,590

CAT E$118,889

View Full Results Thank You For Your Subscription.